SEDA CHAIR

AndreuWorld 2019 International Design Contest Submission

Partnered with Tiancheng Yang

CONCEPT

According to research, “…Americans are sitting an average of 13 hours a day and sleeping an average of 8 hours resulting in a sedentary lifestyle of around 21 hours a day.” It is crucial to design a versatile seating that fulfills all the needs of any individual user in their daily routines. Seda Chair’s sash-like curvature structure is indubitably the soul of this design. Inspired from a dream, a fairy with a floating silk sash is where this conceptual form originated. No extra lines or needless profiles disturb our vision, the shape is defined solely by two simple, organic, and delicate curves. The combination of wood and metal embodies the perfect mix of tradition and modernity. Retaining the memories of history, the unique texture of wood pays respect for the past. Metal, on the other hand, captures subtle details extremely well and adds a new chemistry to our equation – a material relatively malleable for precise molding and casting, and its physical properties allows the frame to be lighter and stronger. The great union of wood and metal emphasizes the importance of the relationship between humans and their environments.

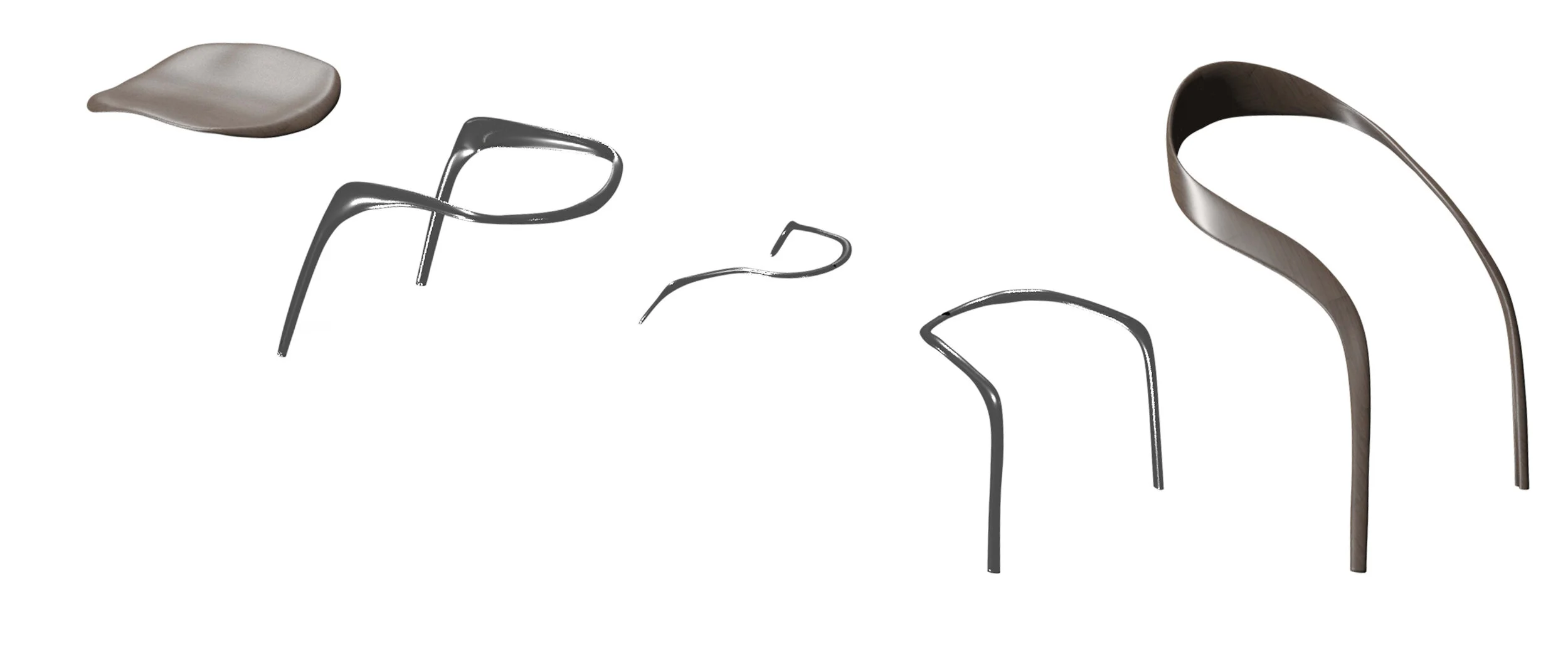

design process

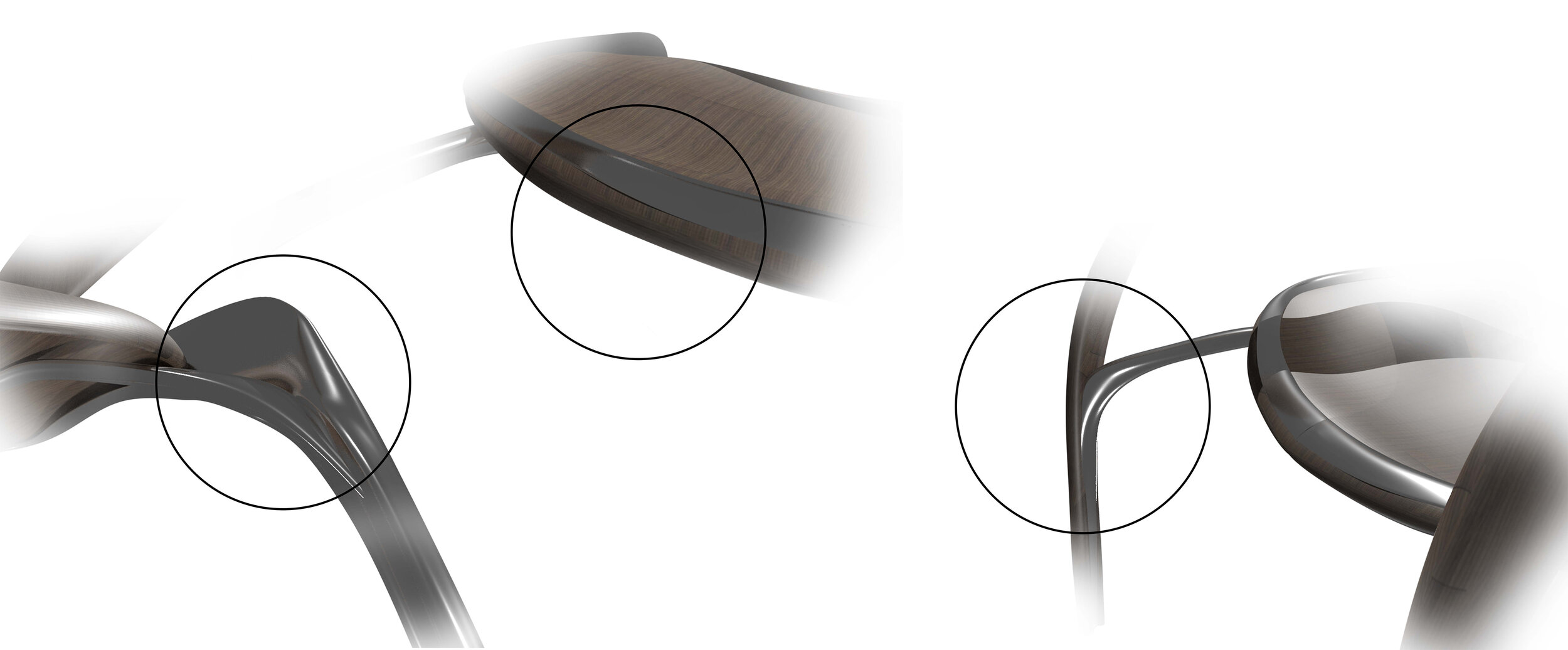

We persist that comfortability is one of our top priorities. The design is essentially made up from two distinct curves. The first curvature begins at a height right below a person’s shoulder blades, with a surface large enough for comfort; it smoothly thickens by each consecutive inch and begins to bend inward in a folding manner that allows users to freely rest their arms generously as armrests. The flatness of its profile also enables comfortable gripping for relaxing arms of any size. The sash ends arching downwards to the ground acting as a foot. This entire structure is a back cushion, an armrest, a grip, and a chair foot all at the same time. As for the remaining curve, it bears not only the main structural load of the entire design, but also its finest details. This piece is molded in a way that the sash structure, the molded seating unit, and the partially hidden X frames all converge into one contiguous blend.

Each angle is precisely calculated to ensure the stability and comfort when in use. The backside of the seat is tilted slightly downwards and pinched near the perimeter to prevent a person from sliding backwards when sitting, and the backrest pulls up near the center of the user's back. The angle between the sitting and the back is exactly 105 degrees along with 4 degrees angle between the seat and the horizontal plane. A reclining seat and back will shift weight to the occupant's back. Maintaining this state achieves a comfortable and very generous sitting posture. Furthermore, the X-shape structure sustains and distributes the user’s weight to each leg equally, which offers the most stable and durable support. These small details, as often neglected as they are, make the greatest differences in the quality of the product.

We find that curves are easily fueled into different environments as a soft design feature. It is the perfect short-term seating that can be used in the lounging area for work and leisure, or in the waiting area of a luxury hotel. The simplistic curvature concept of the design is meant to be an icon in and of itself, purposefully designed so that this icon can be easily applied on further iterations and variations further down the road

ENVIRONMENT & ECONOMY

As an integral part of our design conversation, we meditate on the possible ramifications of our design through its life cycle – from its inception, its fabrication process, to the end of its very life. The emission of carbon dioxide during harvesting, transportation, and use is far less than that of fixing in trees. Our main component is American Walnut. It has a common Janka rating of around 1010 – hard enough for structural support in a chair, but soft enough that its natural lifecycle does not become an issue. Oak, for one, are far stronger but their durability comes at the cost of time for maturity and as such not the most ideal for sustainability. We use recycled metal for the rest of the structural frames. It takes less energy to turn scrap metal into a new product than to harvest new resources to do the same exact thing. Making use of existing materials reduces the mineral extraction, which in turn contributes to the preservation of natural landscapes.

Regarding economy and cost, the highly precise metal and wood bending requirements are surely the most time-consuming (relatively speaking) and costly parameters of this chair. A simple piece of wood belt and a wood sitting pad with four metal legs and some screws are all the required assemblies for the Seda chair.